Explore Portable HVAC Systems – Compare Solutions for Garages, RVs, and Workshops

Outline

- Portable HVAC Types for Tough Spaces: What Works Where and Why

- Sizing and Load Calculations for Garages, RVs, and Workshops

- Venting, Moisture, and Air Quality: Comfort Without Compromise

- Power, Noise, and Mobility: Living With Your Portable System

- From Shopping Cart to Comfort: Checklists, Setup, and Final Thoughts

Introduction

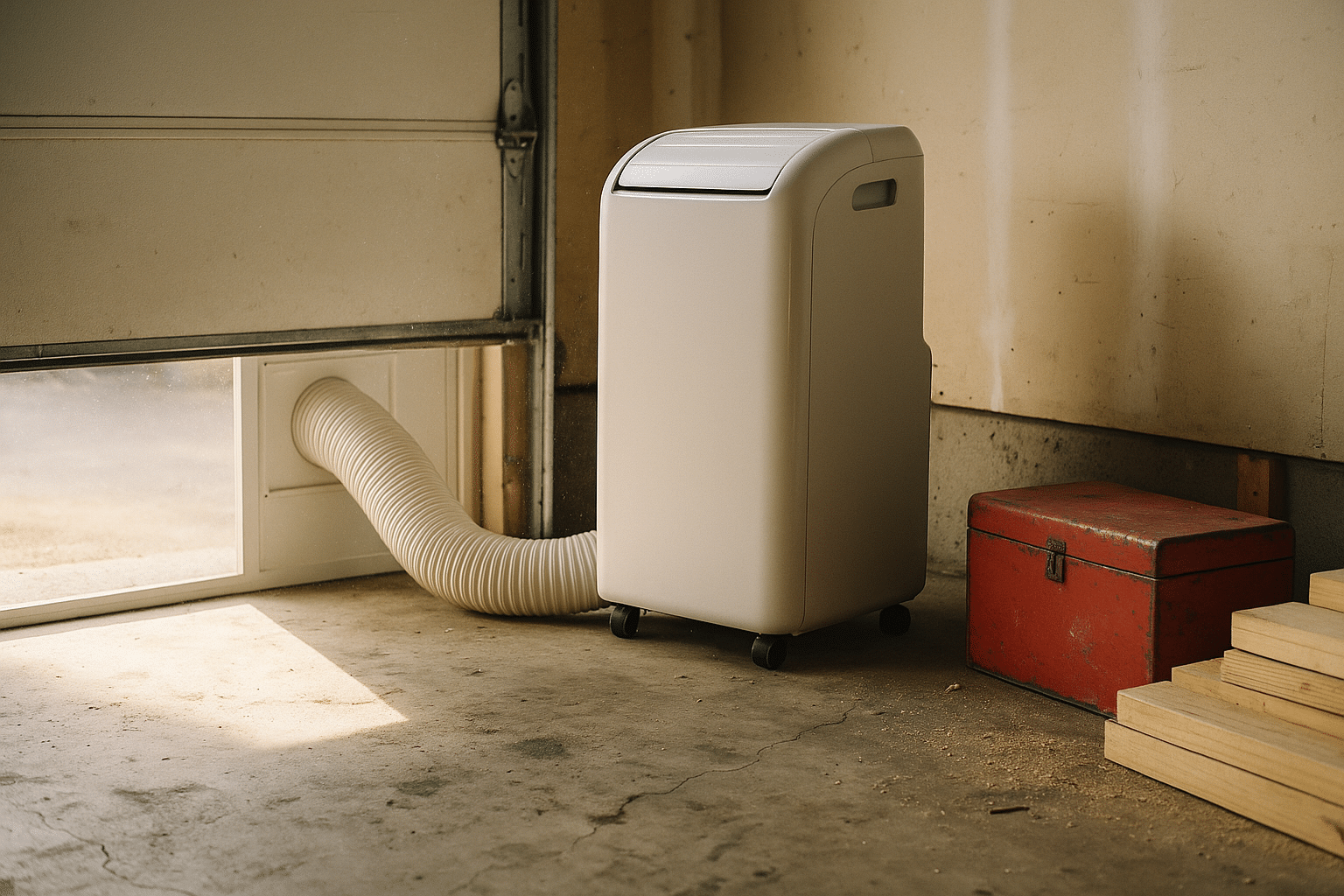

Garages, RVs, and workshops challenge conventional heating and cooling. They’re often leaky, sun-baked, or filled with tools and materials that add heat and humidity. Portable HVAC systems offer a flexible way to create comfort without tearing into walls or committing to permanent installations. The right choice improves not only temperature but also safety, productivity, and energy use. Below, you’ll find a clear breakdown of equipment types, accurate sizing methods, venting and moisture practices, and real-world considerations for power, noise, and mobility—so you can pick a solution that actually fits your space and your life.

Portable HVAC Types for Tough Spaces: What Works Where and Why

Portable HVAC is not one thing—it’s a toolbox of technologies. Choosing wisely starts with understanding how each option works and where it shines.

Portable air conditioners (single-hose) pull indoor air to cool their condenser and exhaust warm air outside through a hose. They’re easy to set up but can create slight negative pressure that draws hot, dusty, or humid air from outdoors or adjacent spaces. Dual-hose portable ACs use one hose for intake and one for exhaust, reducing pressure imbalances and often improving efficiency in semi-conditioned garages and workshops. For sizing, look at the seasonally adjusted cooling capacity (SACC), a standardized rating that reflects realistic performance; many common units list nominal capacities around 10,000–14,000 BTU, with SACC typically lower in the 5,000–12,000 BTU range.

Portable heat pump ACs add reversible operation—cooling in summer and heating in shoulder seasons. When outdoor temperatures hover above freezing, their coefficient of performance (COP) can be roughly 2–3, meaning they deliver 2–3 units of heat per unit of electricity. That can be far more economical than electric resistance heaters for RVs or well-sealed workshops. In colder snaps, their heating output declines, so pairing with a supplementary heater or using them mainly for three-season comfort is a practical plan.

Evaporative coolers (often called swamp coolers) can feel like magic in hot, dry climates. They pull air through wetted media, adding moisture while dropping air temperature by several degrees. In humid regions they perform poorly and can raise indoor humidity to uncomfortable levels—less than ideal for garages storing tools or workshops where materials need dry conditions. However, in arid locations, they’re energy-efficient and effective for open garages with frequent door cycling.

Electric space heaters are straightforward: plug in and heat. Ceramic or oil-filled models provide steady warmth but consume significant power (commonly 1,000–1,500 W). In a well-insulated single-car garage or small RV, they can take the edge off cold mornings. For larger spaces, portable heat pump ACs are generally more energy-efficient when temperatures allow.

Combustion heaters (propane or diesel) can deliver strong heat output, but safety and ventilation are non-negotiable. Unvented combustion adds moisture and combustion byproducts to indoor air. In enclosed garages and workshops, prioritize vented options and maintain adequate airflow. Always use carbon monoxide detectors and follow manufacturer clearances. In RVs, many owners rely on built-in vented systems; if you supplement with portable heat, ensure it’s designed for indoor use and follow all safety guidance.

Dehumidifiers are unsung heroes. Lowering relative humidity to 40–50% can make a workshop feel noticeably cooler, protect tools from rust, and support finishes and adhesives. Many portable ACs dehumidify incidentally, but a dedicated unit gives you control in shoulder seasons or transitional weather.

- Good fits by space:

- Garages: Dual-hose portable AC or portable heat pump, plus dehumidifier.

- RVs: Compact heat pump AC when on shore power; electric heater as backup.

- Workshops: Dual-hose AC for cooling, heat pump for shoulder seasons, dedicated dehumidifier for material protection.

Matching the technology to your climate, enclosure, and activities is the foundation for comfort that lasts.

Sizing and Load Calculations for Garages, RVs, and Workshops

Right-sizing is the most important step you can take. Undersized units run constantly without satisfying the setpoint; oversized units short-cycle, waste energy, and may leave the air clammy.

Start with area and envelope quality. For rough planning, many residential guides suggest 20–30 BTU per square foot for moderately insulated spaces. Detached garages and workshops are often leakier and may need more. Use these as baseline starting points and adjust:

- Garage (poor insulation, frequent door openings): 30–40 BTU/ft² for cooling in hot climates; 25–35 BTU/ft² in milder areas.

- Workshop with heat-generating tools: Add 3,000–6,000 BTU for equipment and task lighting during peak use.

- RVs (150–300 ft²): 7,000–13,500 BTU nominal AC units are common; focus on SACC for portable units to reflect real performance.

Example: A 2-car garage (~400 ft²) with sun exposure and limited insulation might need 14,000–18,000 BTU nominal cooling. A dual-hose portable AC with a SACC around 8,000–10,000 BTU can be workable if you improve air sealing and shade the door, while a portable heat pump of similar capacity can handle shoulder-season heating.

Heat and moisture loads matter. Every person adds roughly 250–400 BTU/h; power tools convert electricity into heat in the space, and vehicles recently parked radiate heat for hours. If you run a table saw and shop lights for an afternoon, assume a few thousand extra BTU/h. In RVs, cooking, showers, and breathing add moisture—dehumidification capacity (pints/day) can be as important as cooling BTUs for comfort.

Insulation upgrades change the math. Adding R-13 to garage walls and R-19 or higher to the ceiling often reduces required cooling by several thousand BTU. Sealing top plates, outlet penetrations, and bottom plates has an outsized impact because portable ACs can depressurize a space; every crack becomes a hot-air straw in summer.

For heating, think in watts and COP. A 1,500 W electric heater outputs about 5,100 BTU/h. A portable heat pump delivering the same heat at COP 2.5 draws roughly 600 W. In mild winters or shoulder seasons, that’s a meaningful energy advantage. Below freezing, heat pump capacity declines; plan accordingly or use a safe, properly vented supplemental heater.

Finally, examine ratings carefully:

- SACC (portable AC): Reflects performance under standardized, realistic conditions. Prioritize SACC over inflated nominal ratings.

- CEER (combined energy efficiency ratio): Higher numbers indicate better efficiency; many portable ACs fall in the 8–10 range.

- Dehumidifier capacity: pints/day at standard test conditions; real-world removal falls as air dries out.

A short sizing checklist: measure square footage, assess insulation and air leakage, estimate internal gains (people, tools, sun), then select capacity by SACC/CEER and dehumidification needs. This procedure turns guesswork into a plan.

Venting, Moisture, and Air Quality: Comfort Without Compromise

Efficient venting and moisture control separate “it runs” from “it works.” Portable ACs move heat outdoors via ducting; how you route those hoses materially affects performance and indoor air quality.

Single-hose systems are convenient but can draw outdoor air in through cracks, which reduces net cooling. Dual-hose units pull intake air from outside and exhaust it back out, limiting pressure changes and often improving comfort in leaky garages and workshops. Whichever you choose, keep hoses short and straight; long runs and kinks add static pressure that cuts capacity. Warm hoses also radiate heat back into the room—insulating ducts can help in hot garages.

Window kits are standard in homes, but garages may not have windows. Common workarounds include door-panel adapters, a trimmed panel at the bottom of a partially closed garage door, or a dedicated vent through an exterior wall. Any modification should be sealed to prevent air infiltration and weather damage. If you rent or need a reversible setup, look for compression-fit or sliding-door inserts that don’t require drilling.

Moisture management is crucial. Hot, humid air feels heavier and forces ACs to work harder. Aim for 40–50% relative humidity for general comfort and tool protection. Many portable ACs self-evaporate condensate, but in muggy regions, you may still need to drain a reservoir or connect a gravity drain. In workshops, a standalone dehumidifier can maintain RH targets without overcooling during spring and fall.

Air quality matters as much as temperature. Workshops generate dust; garages can harbor fumes; RVs concentrate indoor emissions from cooking and off-gassing materials. Consider:

- Filtration: Washable prefilters capture coarse dust; adding a separate portable air cleaner with a high-efficiency filter can reduce fine particles during sanding or finishing tasks.

- Ventilation: Targeted exhaust fans near sources (e.g., near a workbench or paint station) help remove contaminants at the source. Even a modest 100–200 CFM fan can make a noticeable difference.

- Combustion safety: If using any combustion-based heater, ensure ample ventilation, maintain clearances, and install CO detectors. Unvented combustion is not suitable for enclosed or sleeping spaces.

Thoughtful air movement strategy—cooling plus filtration plus source control—maintains comfort without trading away health.

Lastly, think seasonally. In winter, sealing and dehumidifying a workshop curbs rust and protects finishes. In summer, shading doors, adding reflective curtains, and insulating the garage door reduces load before your portable unit even turns on. Air that never warms up is air you never have to cool.

Power, Noise, and Mobility: Living With Your Portable System

Portable HVAC earns its name by rolling in when you need it and stowing when you don’t. To make that convenience seamless, plan for power availability, sound levels, and the realities of moving equipment around busy spaces.

Power: Most portable ACs and heat pumps for residential use run on 120 V circuits and draw 8–12 amps under steady operation, with higher spikes at startup. A dedicated 15–20 A circuit helps avoid nuisance breaker trips. In garages, map your outlets and avoid sharing the circuit with heavy tools while cooling. In workshops, stagger tool starts so compressor loads and motor inrush currents don’t coincide.

RVs bring their own constraints. A 30 A shore-power connection can usually handle a single air conditioner plus small loads; 50 A service opens more headroom. If you rely on a generator, check continuous and surge ratings against your HVAC unit’s start-up profile. Inverter generators often handle variable loads more smoothly and may run quieter in campgrounds. Always follow safe cord routing and weather protection practices.

Noise: Portable ACs typically operate around 50–65 dB at a few feet—conversational but noticeable, especially in the reflective acoustics of a garage. Heat pumps and dehumidifiers are often on the lower end when running at partial capacity. Placement helps: keep the unit off resonant surfaces, avoid corners that amplify sound, and run at lower fan speeds when possible. Soft flooring pads can reduce vibration transfer.

Mobility: Many portable units weigh 50–80 pounds. Look for sturdy casters, handholds, and a compact footprint if you’ll roll the unit between a garage bay and a workshop corner. Hose length matters: most portables include 4–6 feet of duct; extending beyond manufacturer limits cuts performance. For RVs, secure any portable unit during travel and avoid operating on the move. Condensate management—via internal tanks, gravity drains, or lift pumps—should match how you plan to use the space.

Operating cost: A typical portable AC drawing 1.2 kW for 8 hours consumes about 9.6 kWh. At $0.15/kWh, that’s roughly $1.44 for a day’s use. An electric space heater at 1.5 kW for 8 hours uses 12 kWh (~$1.80). A heat pump with COP 2.5 delivering similar heat might draw ~0.6 kW, or 4.8 kWh over 8 hours (~$0.72). While rates vary, these comparisons highlight why heat pumps are attractive in mild conditions.

Durability and maintenance: Washable filters keep airflow up; dust-choked coils kill performance. In workshops, plan a quick filter rinse weekly during heavy use. Check hoses and gaskets for leaks every season. If you store the unit over winter, drain condensate completely and coil hoses loosely to prevent cracks. A small routine keeps your portable HVAC responsive when the heat—or cold—arrives without warning.

From Shopping Cart to Comfort: Checklists, Setup, and Final Thoughts

Portable HVAC pays off when equipment, space, and habits line up. Use these targeted checklists to translate specs into real comfort.

Garage checklist:

- Envelope: Add basic weatherstripping and insulate the garage door if possible; shade sun-facing doors.

- Capacity: Calculate 30–40 BTU/ft² for hot climates, then select by SACC; dual-hose design preferred.

- Venting: Plan a sealed door-panel or wall vent; insulate hoses and keep them short.

- Moisture: Aim for 40–50% RH; add a dehumidifier if the AC cycles off frequently in humid weather.

- Power and layout: Dedicate a 15–20 A circuit; place the unit to avoid tripping hazards and keep intake/exhaust clear.

Workshop checklist:

- Load: Add 3,000–6,000 BTU for equipment when sizing; consider heat pump for shoulder seasons.

- Air quality: Pair your cooling with a dust control plan—source capture and periodic air cleaning.

- Noise: Place the unit away from resonant corners; use vibration pads; consider partial-speed operation.

- Maintenance: Rinse filters weekly during dusty projects; check seals and drain lines monthly.

RV checklist:

- Footprint: Choose a compact unit that can be secured during travel; confirm hose routing to a window or vent.

- Electrical: Match to 30 A or 50 A service; verify generator capacity and avoid overloading circuits.

- Humidity: Manage moisture from cooking and showers; consider a small dehumidifier in humid regions.

- Safety: Use CO detectors; ensure any supplemental heater is designed for indoor use and follow clearances.

Setup tips that punch above their weight:

- Pre-cool or pre-heat: Start units 30–60 minutes before peak use; surface temperatures lag air temperature.

- Zoning: Use curtains or temporary barriers to reduce the conditioned area when you’re only using part of the space.

- Airflow tuning: Point supply air across the room—not directly at a thermometer—to avoid short-cycling.

- Seasonal switchovers: In spring and fall, let a dehumidifier handle moisture while opening windows for mild temperature days.

Conclusion: Portable HVAC for garages, RVs, and workshops is about aligning expectations with physics. Leaky spaces and mobile living demand equipment that’s flexible, efficient under real conditions, and easy to vent and maintain. By sizing to SACC rather than headline numbers, sealing obvious leaks, and planning for moisture and air quality, you turn “hard-to-condition” into “well-managed.” RV owners gain quiet evenings and drier mornings on shore power. DIYers and hobbyists get a less sweaty, less dusty workspace that protects tools and materials. And garage tinkerers finally have a place where projects can stretch into the afternoon without the discomfort tax.

The right unit isn’t a single superlative choice—it’s the one that matches your square footage, climate, electrical capacity, and tolerance for noise and maintenance. Choose thoughtfully, set it up carefully, and let comfort follow.